|

|

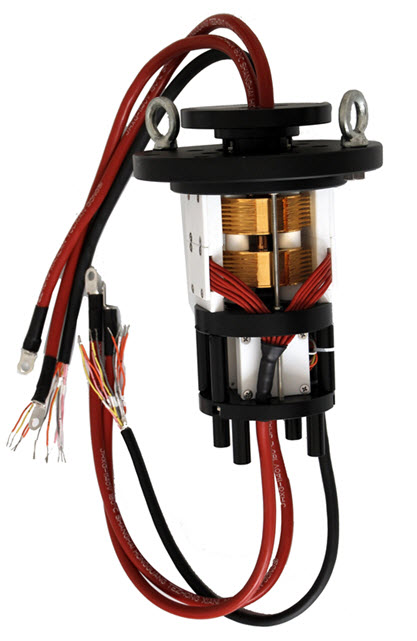

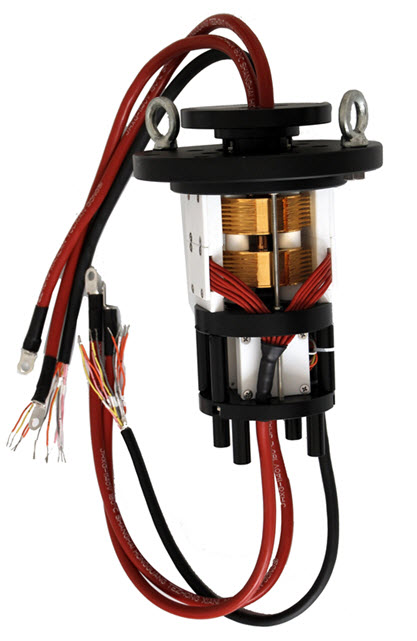

Low Frequency Slip Ring

|

|

Description of our low

frequency slip ring:

- One piece

structure covering both the rotor and stator. Compact structure with small size

for convenient installation, mainly for

transmission of low current and low frequency

signals.

- The through hole can be realized at the

axis center.

- Superposition

of electrical path along the axial direction,

adopting gold to gold multi-points contact

between the brush and the ring with least

friction coefficient, contact resistance and

resistance fluctuation.

- Endurable with

long working life.

- Insulation

materials with excellent electric properties are

used between adjacent electrical paths.

- Insulation and

shielding treatment well handled on the power

and signal channel accordingly.

- Capable of

adapting to various environment such as high

temperature, low temperature, impacting,

vibration, salt spray, damp heat, water

saturation, and etc.

Features of our low

frequency slip ring:

- Compact design

with small

size and dimension.

- Flexible structure, easy and

convenient for installation.

- Low

temperature rising during power transmission.

- With least

electromagnetic radiation.

- Strong

anti-interference signal transmission with least

loss

- Strong

adaptation to various environment.

- Wide

applications fields.

- Can be

integrated with optical fiber/liquid (gas) rotary joints.

-

Maintenance-free during working life.

Typical Applications of our

low frequency slip ring:

- Various

Telecommunication Systems.

- Radar Systems.

- Fire Control Systems.

- Precision

Detection Machines.

- Robots.

Customized Options:

- Outline

dimensions.

- Installation

size and installation mode.

- Materials of

housing.

- Surface

treatment.

- Electrical

connection (Wiring and connector).

- Experiment

projects.

|

|

Parameters of our low

frequency slip ring:

|

Content |

Standard |

Options |

|

Environmental Parameter |

Enclosure |

IP54 |

IP68 |

|

Operating Temperature |

-40℃~+60℃ |

-60℃~+60℃

/ 0℃~+150℃ |

|

Operating Humidity |

≯95% |

1 |

|

Electric Parameters |

Voltage Rating |

≤380VAC |

3.5KV |

|

Current Rating |

≤40A |

200A |

|

Electrical Noise |

≤0.01Ω |

≤0.003Ω |

|

Insulation Resistance |

500MΩ@500VDC |

1000MΩ@5000VDC |

|

compression strength |

1500VAC |

10KVAC |

|

Signal Parameters |

Signal Types |

Audio, video, under 100 KBPS digital

signals, control signal, bus signal and

sensor signals |

|

Signal Channels |

≤40 |

≤150 |

|

Electrical Noise |

≤0.01Ω |

≤0.003Ω |

|

Mechanical Parameter |

Rotary Rate |

0~100rpm |

500rpm |

|

Center Through Bore |

≤100mm |

≤300mm |

|

Life(*) |

≥10 million r |

≥40 million r |

|

* Depends on product application. |

|

|

|

|

We are in a good position to design electric slip

rings to withstand the extreme conditions that are

often encountered in outdoor and marine

applications. From wind turbines and outdoor

pan-tilt heads to marine cable reels and downhole

inspection equipment, these harsh environment

electric slip rings are durable and reliable enough

for even the most demanding applications.

Our high-performance

slip ring products are designed for use in a wide range of high-end OEM applications. We pride ourselves in our ability to provide the right precision solution for the right application.

We produce a wide variety of electric motors and slip ring assemblies, including miniature capsule slip rings, through hole slip rings,

RF slip rings, compound slip rings, split slip

rings, large power slip rings, deep water slip

rings, ethernet slip rings, and etc. Our substantial product offering enables us to address all slip ring applications.

China TrueSci offers quick, cost-effective customization of our products to meet your unique specifications. Slip rings ensure engineering and design teams no longer require timely – and often costly – workarounds in order to power rotating devices, whether they be motors, military devices or rotating electrical assemblies. Playing a major role in improving mechanical performance, as well as simplifying operations, they have further further eliminated the threat of damaged and hazardous wiring and cable connections in moving joints.

Slip rings handle either power, data or both across a number of rings on which a spring or other loaded contact finger, ring or brush is held in place to pass power as the rings rotate.

Power levels range from milliwatts to hundreds of kilowatts dependent on application.

|

|