|

|

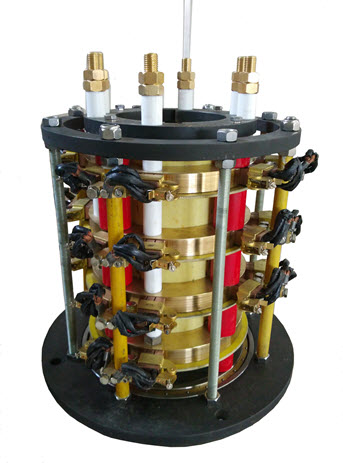

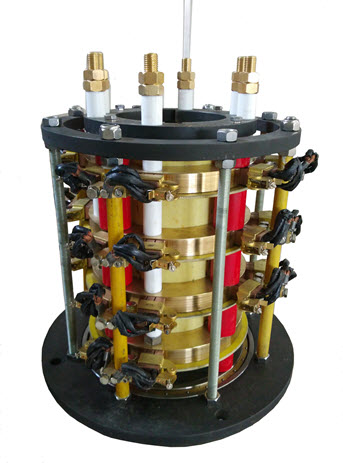

Large Power Slip Ring

(Central Electric Collection Slip Ring)

|

|

Description of our large

power slip ring:

- Our large

power slip rings are usually installed at the

rotary center of the equipment and used to for

transmission of high current and various signals

between the stationary platform and the rotating

platform.

- The large

power slip

rings adopt high quality copper-graphite brushes or silver-graphite brushes

according to the real application, with least contact resistance and electrical sliding wearing and mechanical wearing.

It has very little temperature rising.

- The low

frequency (LF) signal adopts gold to gold

contact with least transmission loss for long

working life.

- High current

and signal use electric sealing structure to

realize high efficient insulation and shielding.

- Both the rotor

and stator have their own independent wiring

box, maintenance window and observation window.

Features of our high power

slip ring:

- Compact design,

requiring just small installation space.

- Easy for

installation and convenient for maintenance.

- High

concentricity and good capability of

anti-tilting.

- Keep little

temperature rising under high current.

- Reliable and

stable under high voltage, with excellent

insulation performance.

- Capable of adapting to various environment such as high temperature, low temperature, impacting, vibration, salt spray, damp heat, and etc.

- Can be

integrated with optical fiber, RF, liquid (gas) rotary joints.

- Available with

optional accessories of heating and dehumidifying

fixture and heat-dissipating fixture.

Typical Applications of our

high power slip ring:

- Ocean and Sea

Machinery.

- Heavy

Industrial Machinery.

- Tunnel Shield

Machine.

- Large Power

equipment.

Customized Options:

- Outline

dimensions.

- Installation

size and installation mode.

- Materials of

housing.

- Surface

treatment.

- Electrical

connection (Wiring and connector).

- Experiment

projects.

|

|

Parameters:

|

Content |

Standard |

Options |

|

Environmental Parameters |

Enclosure |

IP40 |

IP67 |

|

Operating Temperature |

-40℃~+60℃ |

-60℃~+60℃/0℃~+150℃ |

|

Operating Humidity |

≯95% |

100% |

|

Electric Parameters |

Voltage Rating |

≤690VAC |

10KV |

|

Current Rating |

≤1200A |

3000A |

|

Electrical Noise |

≤0.01Ω |

≤0.003Ω |

|

Insulation Resistance |

1000MΩ@1000VDC |

1000MΩ@5000VDC |

|

Withstand Voltage |

2000VAC |

30KVAC |

|

Mechanical Parameters |

Rotary Rate |

0~30rpm |

100rpm |

|

Central Thru Bore |

≤300mm |

1000mm |

|

Life(*) |

≥8 million r |

≥20 million r |

|

* Depends on product application |

|

|

|

|

We are in a good position to design electric slip

rings to withstand the extreme conditions that are

often encountered in outdoor and marine

applications. From wind turbines and outdoor

pan-tilt heads to marine cable reels and downhole

inspection equipment, these harsh environment

electric slip rings are durable and reliable enough

for even the most demanding applications.

Our high-performance

slip ring products are designed for use in a wide range of high-end OEM applications. We pride ourselves in our ability to provide the right precision solution for the right application.

We produce a wide variety of electric motors and slip ring assemblies, including miniature capsule slip rings, through hole slip rings,

RF slip rings, compound slip rings, split slip

rings, large power slip rings, deep water slip

rings, ethernet slip rings, and etc. Our substantial product offering enables us to address all slip ring applications.

China TrueSci offers quick, cost-effective customization of our products to meet your unique specifications. |

|