A slip ring is a vital

electromechanical device that enables the transfer of

power and electrical signals from a stationary platform to a rotating

structure. A slip ring can be used in any electromechanical

system or machine/equipment that requires rotation while transmitting

the power or signals, such as those found in radar antenna, gun turrets, periscopes, electro-optic sensor gimbals, space satellites,

and etc. Slip ring can excellently improve inside the system

the mechanical performance, simplify

system operation and eliminate damage-prone wires dangling

from movable joints.

The slip ring is also called rotating

electrical connectors, rotary electrical interfaces,

swivels, collectors, or electrical rotary joints, these

rings are commonly found in slip ring motors, electrical

generators for alternating current (AC) systems and

alternators and in packaging machinery, cable reels, and

wind turbines. It has become a commonplace component in many of today’s industrial, military and even everyday equipment/machine, where they play a crucial role. They can be used on any rotating object to

transmit power, control circuits, or analog or

digital signals including data such as those found on

aerodrome beacons, rotating tanks, power shovels, radio

telescopes or heliostats.

|

|

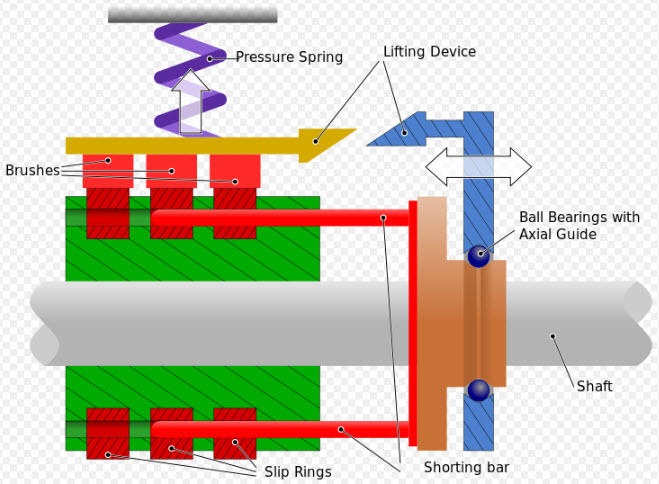

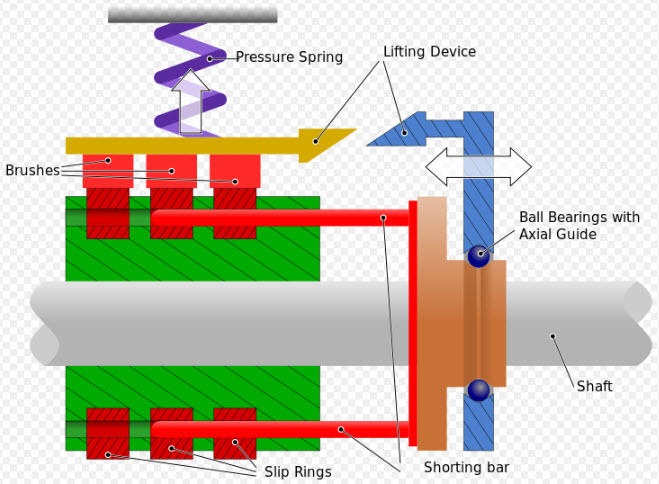

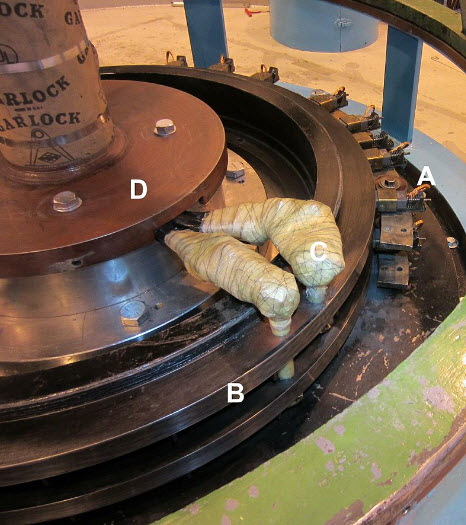

Sketch

of a cross-section of slip rings for an electric

motor. In this example, the slip rings have a

brush-lifting device and a sliding contact bar,

allowing the slip-rings to be short-circuited when

no longer required. This can be used in starting a

slip-ring induction motor, for example. |

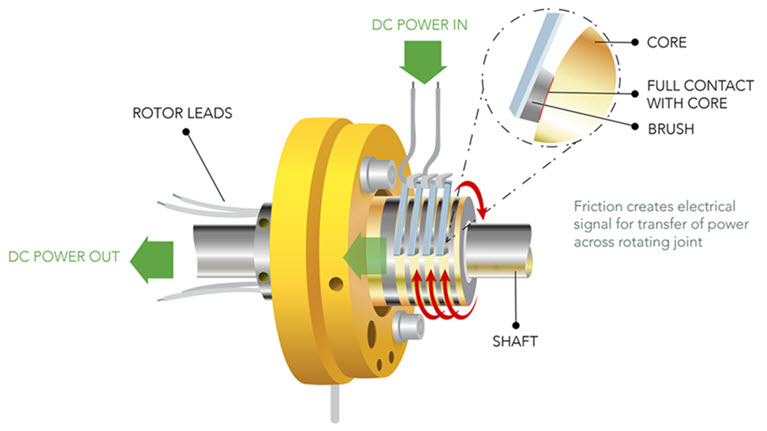

A slip ring (in electrical engineering terms) is a method of

making an electrical connection through a rotating assembly.

Formally, it is an electric transmission device that allows

energy flow between two electrical rotating parts, such as

in a motor. Slip rings handle either power, data or both across a number of rings on which a spring or other loaded contact finger, ring or brush is held in place to pass power as the rings rotate.

The power levels range from milliwatts to hundreds of kilowatts dependent on

the real application. In all applications, frictional wearing is the main determinant of the lifecycle of the slip ring.

Slip ring products can be designed in a variety of configurations. For example they can provide an open through-bore to accommodate other components such as a fluid joint or a wave guide. Instead of a drum the rings can be configured in a platter or pancake. This is appropriate if the space available for the slip ring is short and wide instead of tall and narrow.

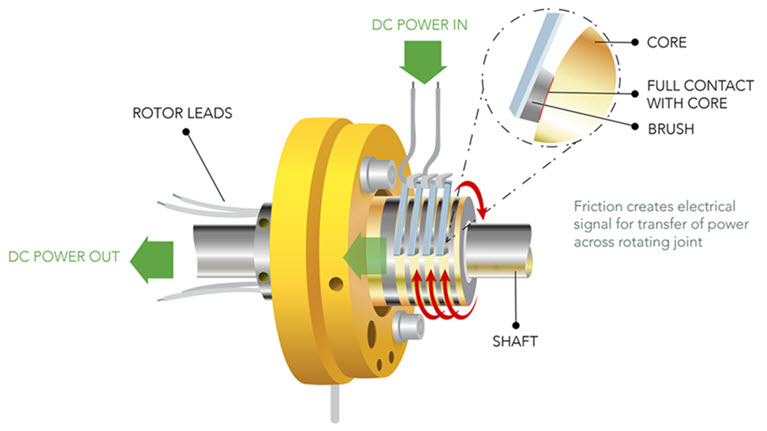

Typically, slip ring is constituted by a stationary graphite or

metal contact (brush) which rubs on the outside diameter of

a rotating metal ring. At a very elementary level, a slip ring is comprised of two major components – a metal brush, and a metal ring. The “brush” can look like a brush made from metal fibers, but more often it looks like a single wire or a spring with a pad of material affixed to the end that contacts the ring. As the metal ring turns, the electric

current or signal is conducted through the stationary brush

to the metal ring making the connection. Additional

ring/brush assemblies are stacked along the rotating axis if

more than one electrical circuit is needed. Either the

brushes or the rings are stationary and the other component

rotates. This simple design has been used for decades

as a rudimentary method of passing current into a rotating

device.

The ring itself is a band of electrically conductive material, mounted on a shaft. Although it’s insulated from the shaft itself, the slip ring is connected to the rotor or rotating assembly through windings or other electrical connections.

The outer part of this slip ring remains in continuous sliding contact with the stationary brushes – or other stationary conductors – which provides either intermittent or continuous rotating devices with unbroken contact between the rotating assembly and external circuit. This ensures power and data are able to be transmitted at all times.

Both this ring and the brush are contained within a single housing, designed to protect the working parts from harmful environmental factors such as dust and moisture.

|

|

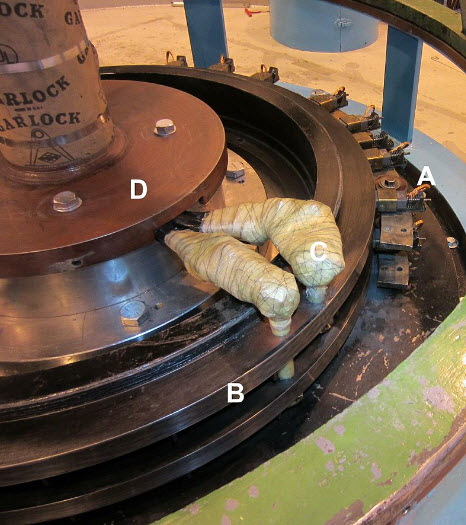

Slip rings on a hydroelectric generator; A - stationary spring-loaded graphite brushes, B - rotating steel contact ring, C - insulated connections to generator field winding, D - top end of generator shaft. |

A critical aspect of slip ring design is the materials used to make the rings and the brushes. After World War II

slip ring

suppliers and manufacturers responded to requirements from the emerging electronics industry with gold plated rings using gold wire brushes. Up until the 1970’s many slip rings used copper rings and graphite brushes. Copper is smooth and conducts electricity well. Graphite conducts well, it is soft, and it does not abrade the copper rings. But for advanced applications such as space satellites and missiles, graphite brushes were inadequate. There was a burst of research and invention in the early years of the space program to address emerging needs, mostly in space and missile programs, that produced advanced gold on gold alloy systems and systems that employed silver alloy rings with brush tips made from silver graphite mixtures. Today these two systems, gold-on-gold and silver/silver-graphite, are the mainstays of the slip ring industry. Gold-on-gold systems are often used for low current signal circuits because they are compact. Silver/Silver-graphite systems are often selected

by

manufacturer of slip rings for higher current power circuits because in these applications they are more economical, and have long service life.

Some other names used for slip ring are collector ring,

rotary electrical contact and electrical slip ring. Some

people also use the term commutator; however, commutators

are somewhat different and are specialized for use on DC

motors and generators. While commutators are segmented, slip

rings are continuous, and the terms are not interchangeable.

Rotary transformers are often used instead of slip rings in

high-speed or low-friction environments.

A slip ring can be used within a rotary union to function

concurrently with the device, commonly referred to as a

rotary joint. Slip rings do the same for electrical power

and signal that rotary unions do for fluid media. They are

often integrated into rotary unions to send power and data

to and from rotating machinery in conjunction with the media

that the rotary union provides.

Slip rings are made in various types and sizes by

slip ring

designer and product developer; one device

made for theatrical stage lighting, for example, had 100

conductors. The slip ring allows for unlimited

rotations of the connected object, whereas a slack cable can

only be twisted a few times before it fails.

The slip

ring engineer should be given the maximum

space available in the system so all existing

candidate designs can be considered. It is

imperative that the space required for the slip

ring be specified in the early stages of the

system design and that it be consistent with

the structural and electrical demands.

Wireless and contactless slip rings do not rely on the typical friction

based metal and carbon brush contact methods that have been

employed by slip rings since their invention, such as those

explored above. Instead, they transfer both power and data

wirelessly via an electromagnetic field, which is created by

the coils that are placed in the rotating receiver, and the

stationary transmitter. Wireless slip rings are

considered an upgrade from - or alternative to - traditional

slip rings, as their lack of standard mechanical rotating

parts means they're typically more resilient in harsh

operating environments, and require less maintenance and

upkeep. Contactless, wireless slip rings are the next generation in inductive power transfer solutions, specifically designed to replace existing, aging mechanical slip ring technology. Moving on from a reliance on friction based metal and carbon brush contact to enable the transfer of power and data, wireless slip rings utilize IPT to transfer power via an electromagnetic field created by coils placed in the stationary transmitter and rotating receiver. By removing the inherent need for friction or contact to generate an electrical current, wireless slip rings significantly reduce the maintenance costs associated with worn mechanical slip rings, while also offering a simple, clean design that’s easily integrated into any application or device.

Today’s slip rings are reliable, have long service life and can be designed for extraordinary environments, including the vacuum of space, the shock of a tank gun turret or the vibration of a helicopter rotor.

Defining System Interface

Requirements

The slip ring engineer will need to know these

system interface considerations:

1. Can the slip ring mount directly on the

center line or is a through-bore required in

the slip ring? A through-bore can be used

to mount the slip ring on a shaft or used for

routing hydraulic lines, pneumatic lines, fiber

optic rotary joint, wave guide. etc.

2. How will the slip ring attach to the system?

A slip ring must be mounted with a flexible

coupling on one side of the unit. Hard

mounting on both the rotor and stator will

cause the slip ring to fail prematurely by

translating system load into the slip ring

bearing structure.

3. How should the electrical connections to

the slip ring be made? Is it desirable to have

connectors integral with the slip ring on both

the rotor and stator, or would flying leads on

one or the other ends be desirable? And if

flying leads are preferred, should they exit the

rotor / stator in a radial or axial direction, and

what length should the leads be?

Defining Electrical

Requirements

The specified current enables the slip ring engineer to

propose a unit with the appropriate cross-sectional area of

the rings, brushes and lead wires. The specified voltage

dictates the spacing between adjacent rings and brushes. It

is helpful in achieving the most cost effective and smallest

practical envelope not to rate all circuits at the maximum

level. For example, if you need 20 circuits total, three of

which must carry ten amps, designate three for high current.

Don’t insist on 100% functional interchangeability by

specifying that all 20 circuits carry ten amps. And, if ten

amps is a surge current with a continuous current of only

two amps, tell us that, too. There is no reason for you to

pay for ten amps continuous capacity when you only need two

amps. Be aware that voltage surges and spikes are the major

cause of system slip ring failures. A conservative approach

can be used to circuit design, however, it is not uncommon

in some power supply systems to see voltage spikes ten or

more times the normal operating voltage. We strongly

recommend surge protection on all power supplies. Most

smaller slip rings will satisfactorily conduct signals to 50

megabits / sec. Special slip rings can be used to pass

broadband signals from DC to 1 gigahertz and data rates of

500 megabits or even higher. Cross-talk, insertion loss and

bit error rate information can be projected, if tested for

actual values, when data rates, formats and impedances are

defined. The appropriate shielding techniques will be

incorporated to meet the system requirements.

Defining Mechanical

Requirements

1. Operating speed (rpm) is an important design parameter.

Almost any slip ring can operate successfully at speeds to

100 rpm although many applications only require operation at

a few rpm. Slip rings are routinely used to instrument test

jet turbine engines operating at speeds in excess of 20,000

rpm. The operating speed, in conjunction with the diameter,

dictates the surface speed of the ring relative to the brush

and hence the internal design approach and material

selection. 2. What rotational life is necessary for your

application? Will the unit oscillate or rotate at a

continuous speed?

The environment in which the slip ring must

survive is a key factor. Operating temperature

range is important in specifying the proper

lubricant. And if the slip ring will operate

exposed to the elements or to a hostile

environment, integral seals must be included

in the design. Any unusual shock or vibration

should also be specified. Where are slip rings most

commonly found?

Slip rings are utilized in a variety of devices across a

broad range of industries. Slip rings are used in systems

that require continuous rotation while transmitting power

and data from a stationary unit to a rotating device. Some of the

slip ring applications include:

TRUCKS & MAN LIFT EQUIPMENT:

Aerial Work Platforms

Bridge Cranes

Platform Cranes

INDUSTRIAL/COMMERCIAL IN-PLANT

EQUIPMENT:

Automated Welding Equipment

Centrifuges

Conveyor Systems

Custom Machinery

Fabrication Equipment

DRILLING & OTHER BORING

EQUIPMENT:

Off-Shore Drilling Rigs

Down hole Drill and Geotechnical Testing

Horizontal Earth Boring & Drilling

SIGNAGE RELATED EQUIPMENT:

Advertising Displays

Exhibits and Displays

MISC. OFF-HIGHWAY HEAVY

EQUIPMENT:

Forklifts

Utility Trucks

Truck Body / Service Cranes

MILITARY PURPOSE

Slip rings have been widely used for military purpose to

meet the demand of various applications.

The increasing complexity of modern military vehicles

demands slip rings to provide reliable electrical interfaces

between the stationary and rotating parts of these vehicles.

Today’s rotorcraft applications place unique demands on slip ring technology because of equipment requirements

and environmental conditions. From de-ice applications (with their need for high rotational speed, exposure to

weather conditions and high vibration) to weapon stations and electro-optic sensor systems (with high bandwidth

signal transmission), helicopter slip rings must perform in a highly reliable mode with the latest product

advancements.

OTHER:

Amusement Rides

Arcade Machines

Unmanned Vehicles

Remotely Operated Vehicles

Car Wash Equipment

Wind Turbines

Commercial Camera

Medical Device

Security Systems

A slip ring is an

electromechanical device that allows the transmission of

power and electrical signals from a stationary to a rotating

structure. Also called a rotary electrical joint, collector

or electric swivel, a slip ring can be used in any

electromechanical system that requires unrestrained,

intermittent or continuous rotation while transmitting power

and / or data. It can improve mechanical performance,

simplify system operation and eliminate damage-prone wires

dangling from movable joints. For high speed data transfer

or for data transfer in EMI sensitive environments, Fiber

Optic Rotary Joints (FORJ’s) can be used. Fiber Optic Rotary Joints (FORJs) are to optical signals what electrical slip rings are to electrical signals, a means to pass signals

across rotating interfaces, particularly when transmitting large amounts of data. FORJs maintain the intrinsic advantages of fiber

end to end.

China truesci supply high-quality slip ring products used in critical defense and space applications. |