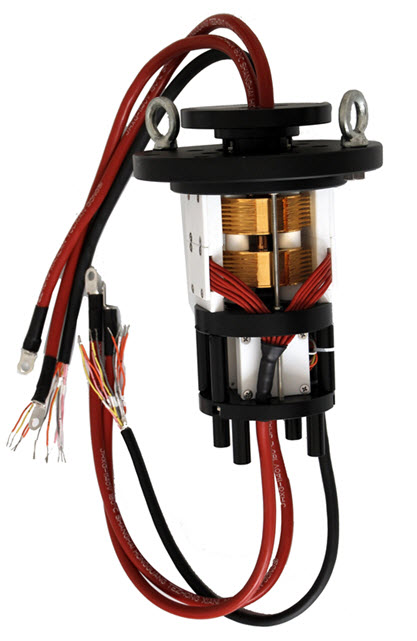

Description:

- One piece

structure covering both the rotor and stator. Compact structure with small size

for convenient installation, mainly for

transmission of low current and low frequency

signals.

- The through hole can be realized at the

axis center.

- Superposition

of electrical path along the axial direction,

adopting gold to gold multi-points contact

between the brush and the ring with least

friction coefficient, contact resistance and

resistance fluctuation.

- Endurable with

long working life.

- Insulation

materials with excellent electric properties are

used between adjacent electrical paths.

- Insulation and

shielding treatment well handled on the power

and signal channel accordingly.

- Capable of

adapting to various environment such as high

temperature, low temperature, impacting,

vibration, salt spray, damp heat, water

saturation, and etc.

Features:

- Compact design

with small

size and dimension.

- Flexible structure, easy and

convenient for installation.

- Low

temperature rising during power transmission.

- With least

electromagnetic radiation.

- Strong

anti-interference signal transmission with least

loss

- Strong

adaptation to various environment.

- Wide

applications fields.

- Can be

integrated with optical fiber/liquid (gas) rotary joints.

-

Maintenance-free during working life.

Typical Applications:

- Various

Telecommunication Systems.

- Radar Systems.

- Fire Control Systems.

- Precision

Detection Machines.

- Robots.

Customized Options:

- Outline

dimensions.

- Installation

size and installation mode.

- Materials of

housing.

- Surface

treatment.

- Electrical

connection (Wiring and connector).

- Experiment

projects.

|

|

|

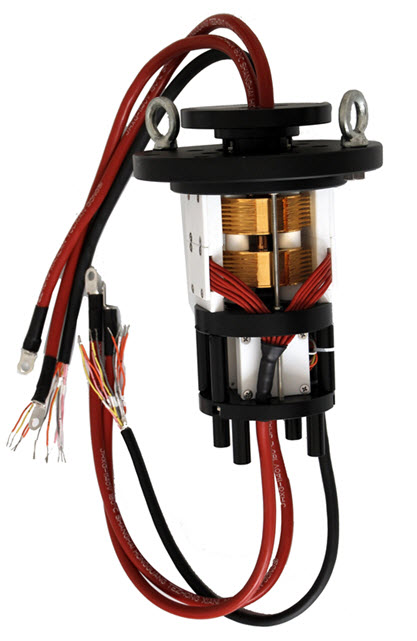

Slip ring assemblies

are used for the transfer of power and data. We can

manufacture customized units that combine power slip

rings with signal/optical/hydraulic rotary joints.

We design slip ring assemblies from concept using

the latest 3D design techniques. We produce virtual

3D images that give a vivid impression of a new

design of slip ring. We are in a good position to

meet customized demand of slip rings.

China TrueSci is a

designer and manufacturer of precise slip ring

assemblies for commercial, industrial, defense and

aerospace applications.

We China

TrueSci put our customers first and we pay top attention to

quality. We deliver reliable slip ring products, competitive pricing, superb technical support, and short lead times through our

capable R&D team and efficient manufacturing processes. Not only do we provide the slip ring, slip ring assembly, and motor assemblies that meet your

special specifications, we offer value-added services to provide you with exactly what is needed quickly and cost-effectively.

We offer the best products in the industry of slip rings accurately.

Please feel free to contact us for high

quality service and reliable products. We treasure the opportunity to

be your best supplier of slip rings. We have the expertise

to design and build slip rings for any application such as

radar system,

military weapons, aerospace equipments, aircrafts, ships,

engineering machinery, industrial robots, oil well logging

tools and security monitors, and etc. We

have been involved in the design and manufacturing of tens

of thousands of slip ring assemblies for all industries. We

know clearly how to build a highly reliable slip ring

assembly and we aim to meet your

unique demand with high efficiency and competitive price.

China TrueSci industrial slip rings provide the solution to transmit electric power and electrical signals from stationary to rotating units in all types of machines like

radar system, antenna dishes, revolving cranes, rotating purifiers in sewage or water treatment facilities, carrousels, manipulators, wrapping machines, theatre stages, wind turbines as well as in cable reels.

Our fully developed and versatile standard program facilitates to assemble slip ring assemblies with any number of poles. Current ratings up to 1200 A and voltages up to 24 kV are possible. The range in size for the slip ring assemblies starts with 30 mm up to 360 mm diameter and lined up to 100-poles.

Slip ring assemblies can be supplied either as open, “non-enclosed” types for special customer adaptations, or totally enclosed with high impact plastic or galvanised steel housing even for hazardous locations. Additional rotating couplings are available for fluids or gases and fiber optic swivels can be integrated.

|